Building Construction Emissions: A Journey Through A1 to D

When people talk about green buildings, the conversation often revolves around smart thermostats, solar panels, and energy-efficient lighting. These are all part of what’s known as operational emissions — the greenhouse gases released during the use of a building. They’re easy to observe, measure, and manage. But beneath the surface, a different type of emission quietly plays an equally crucial role in a building’s environmental footprint: embodied emissions.

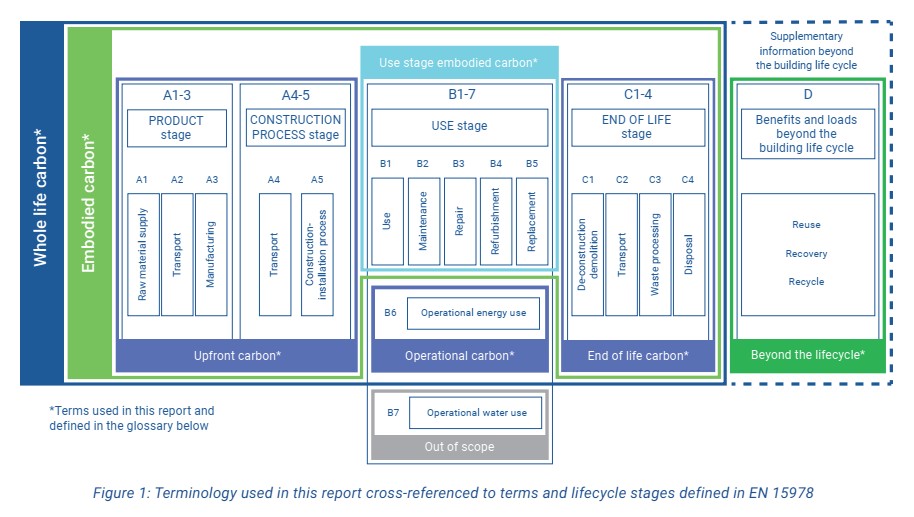

Embodied emissions are the result of all the processes involved in building construction before and after it’s in use. From extracting raw materials to transporting them, manufacturing components, assembling them on site, maintaining the structure over decades, and eventually tearing it down — all of these stages emit carbon. While green building certifications and green building rating tools have historically prioritized reducing operational carbon, the spotlight is now shifting. As operational emissions shrink due to better building performance, embodied carbon is becoming the dominant source of emissions in many high-performance projects.

In fact, embodied emissions can account for up to 50% of a building’s total carbon footprint, especially in buildings designed to operate with net-zero energy. Unlike operational emissions, which occur gradually over the building’s life, embodied carbon is emitted mostly upfront, before anyone even moves in. This “invisible” emission profile often goes unnoticed by clients and developers. That’s why green building consultants are increasingly emphasizing life cycle thinking as part of sustainable design.

To tackle this challenge, the construction industry uses standardized life cycle stages, defined by EN 15978 and ISO 21930. These stages — labeled from A1 to D — help map out exactly where emissions are generated during a building’s lifetime. By understanding these stages, professionals can identify emission hotspots and develop targeted strategies to reduce them.

The life cycle begins with Stage A1, the raw material supply phase. This includes all emissions from extracting and processing building materials — mining limestone for cement, cutting down trees for timber, or refining iron for steel. It’s the first step in a long journey, and one with significant carbon costs. Next is Stage A2, which covers the transport of these materials to manufacturing plants. Depending on the distance and transport method (truck, ship, or rail), this stage can be surprisingly impactful. For example, diesel trucks hauling granite across countries add a heavy carbon burden before construction even begins.

Then comes Stage A3, which involves manufacturing the building products. From rolling steel beams to casting concrete blocks or assembling glass panels, this stage is among the most energy-intensive. Much of the embodied carbon in materials comes from this phase, especially when fossil fuels are used in manufacturing processes. Together, A1 to A3 make up the product stage — the foundational phase of a building’s physical existence.

After materials are manufactured, they’re moved to the construction site, which brings us to Stage A4, the transport to site. This is followed by Stage A5, which includes all emissions from construction activities — fuel used by machinery, power tools, generators, and the management of construction waste. On large sites, these emissions can rival or exceed those of early material production. Reducing waste and optimizing logistics are key strategies here, often guided by green building consultants working to align with certification goals.

Once construction wraps up, the building enters the use stage, or Stage B, which spans years or even decades. This phase includes regular operational emissions such as heating, cooling, lighting, and ventilation (B6), along with repair and maintenance (B2–B5). While green technologies and renewable energy have made it easier to reduce operational emissions, this stage still plays a vital role in the overall carbon picture. It’s also where green building rating tools like LEED, BREEAM, and Green Star typically place the most emphasis, evaluating energy efficiency, water use, and indoor environmental quality.

Eventually, every building must be retired. The end-of-life stage, Stage C, addresses what happens when demolition begins. C1 includes emissions from dismantling the structure — the use of excavators, cranes, and other equipment. C2 involves transporting waste to landfill or recycling centers, while C3 captures the energy used to process that waste. C4, the final disposal stage, includes emissions from materials that can’t be salvaged and must be incinerated or buried. These end-of-life emissions vary greatly depending on local infrastructure and recycling availability.

One of the most innovative aspects of life cycle assessment is Stage D, often referred to as the “benefits beyond the system boundary.” This stage captures emissions that are avoided in the future by recycling or reusing building materials. For example, steel beams removed from a deconstructed warehouse can be reused in a new project, reducing the need to produce virgin steel. These avoided emissions are credited in Stage D and represent a huge opportunity for circular economy thinking in construction. This is where green building consultants often bring the most strategic value—by helping clients design buildings that don’t just perform well now, but offer environmental benefits decades into the future.

Measuring embodied emissions across these stages requires reliable data. This is where Life Cycle Assessment (LCA) tools come in. These digital platforms use Environmental Product Declarations (EPDs) from manufacturers to quantify carbon impacts in kg CO₂ equivalent. Tools like One Click LCA, eTool, and Tally are now widely used in both academic and professional circles. In many cases, LCA modeling is also required or incentivized under major green building certification schemes.

Reducing embodied carbon starts with smart choices. Material selection is one of the most impactful levers. Low-carbon concrete mixes that include fly ash or slag instead of traditional Portland cement can reduce emissions dramatically. Choosing recycled content — such as reclaimed steel or salvaged wood — not only cuts carbon but also gives materials a second life. Efficient structural design is another strategy. By optimizing spans, loads, and layout, engineers can reduce the total volume of materials needed without compromising safety or performance.

Moreover, green buildings can be planned for disassembly and reuse, not just construction. Designing with standard modules, reversible connections, and recyclable materials can extend the usefulness of components long after the original building is gone. Local sourcing also plays a role—materials that travel shorter distances naturally emit less during transport stages (A2 and A4).

For students preparing to enter the built environment profession, and for professionals already shaping our cities, understanding the life cycle stages from A1 to D is foundational. It shifts the focus from short-term performance to long-term responsibility. Every decision, from selecting a material to designing for reuse, influences a building’s carbon story. With the help of green building consultants, rating tools, and certifications, it’s now possible to make buildings not only energy efficient but genuinely low carbon across their entire life.

As the world demands more sustainable infrastructure, the buildings we design, construct, and occupy must tell a better environmental story. And it starts with understanding every chapter — from raw materials to rubble — and rethinking how we define a truly green building.